DonoBeam

Expand the possibilities of your building with DonoBeam.

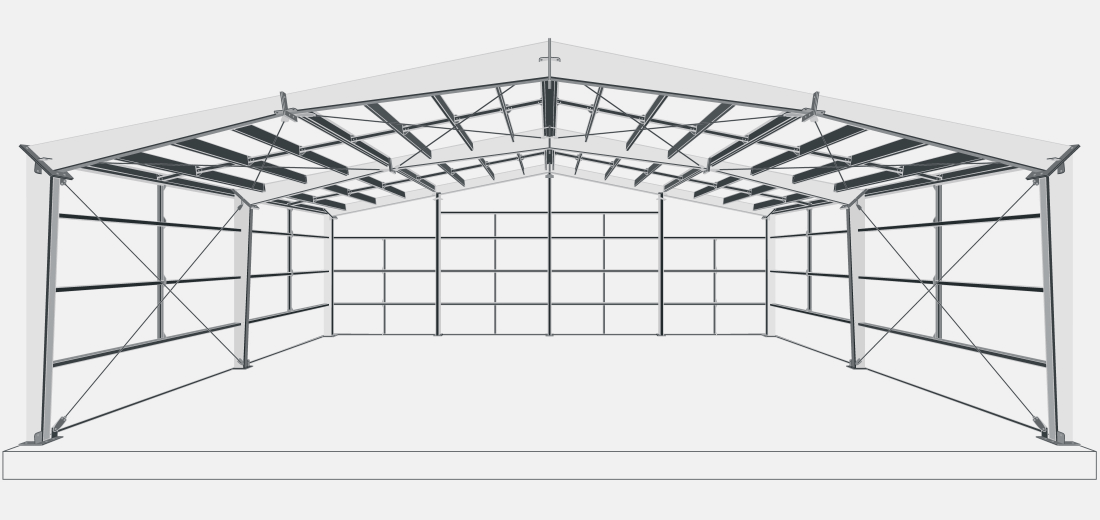

DonoBeam is a tapered metal box beam—manufactured by welding two folded halves of steel plate together to form a box. It’s specifically tapered to reduce the steel needed for any design without reducing structural integrity.

Codeveloped in 2015 with BlueScope Steel, we have designed DonoBeam to withstand harsh New Zealand environmental conditions to protect your new building for years. The steel-saving design offers a more robust design solution (compared to cold-formed sections) for medium to large-spanning buildings and a lighter solution than hot-rolled sections. The result is a trusted product rapidly becoming the most efficient structural solution in the New Zealand market.

Alongside the significant cost-savings in steel, DonoBeam delivers high spans and greater design flexibility. We understand the value of unobstructed internal space, which is why DonoBeam structural steel beams boast economical and impressive clear spans to suit your business needs. This versatile metal box beam system can also incorporate various architectural or practical elements with a unique and distinct aesthetic to make your project stand out.

Due to its prefabricated structure, the entire frame can be assembled safely and quickly on the ground without on-site welding. This equates to less risk and time spent on-site, resulting in significant labour cost savings for you and your business.

The innovative DonoBeam design uses less raw materials and is typically lighter, which results in considerable carbon-savings across the entire lifecycle of a construction project.

A 2021 Building 4.0 CRC study undertaken at Monash University in Melbourne evaluated the potential environmental benefits of the DonoBeam structures compared to traditional systems, using internationally recognised ISO 14040 and ISO 14044 standards for environmental life cycle assessment.

DonoBeam presents an environmentally-conscious solution with up to 40% fewer carbon emissions when compared to conventional steel construction methods. This includes a reduction of up to 25% in steel emissions and up to 26% in transport-related emissions.

Contact Coresteel and experience the benefits of a revolutionary metal box beam structure today.

Structural Points of Difference

-

DonoBeam's torsional stiffness significantly reduces the need for fly bracing

Traditional I-Beam portal frames tend to buckle rotationally under load and lose their strength. To compensate for this, they require a lot of buckling restraints (fly-bracing) to be installed. DonoBeam is significantly more stiffer rotationally, and can carry high loads with minimal buckling restraint. As a result, DonoBeam buildings also look cleaner and more appealing without the cluttered look of fly-bracing.

-

Reduction in steel weight due to tapering of portal structure

DonoBeam frames are designed to be efficient, providing structural strength where it is required and removing material where it’s not. This reduces the overall weight of the structure and makes better use of Earth’s valuable resources.

-

Fully bolted for easy erection

Our structural connections are fully bolted and structural members appropriately sized for easy handling, transport and erection.

-

Easily partners with DonoBrace® - Donovan Group's tension-only bracing system

DonoBrace is the only steel rod bracing product in Australia and New Zealand which is dynamically tested in a simulated earthquake environment.

-

Bird and vermin-resistant sections

DonoBeam frames are fully sealed box sections making them resistant to birds, vermin, and dust. They can be paired with “bird-proof” purlins to create a complete solution for building owners.

-

Fully-welded tapered section

DonoBeam is manufactured by folding two halves of steel plate and welding them together to form a sealed hollow box section. It is tapered through its length, utilising only the amount of steel required for a given design.