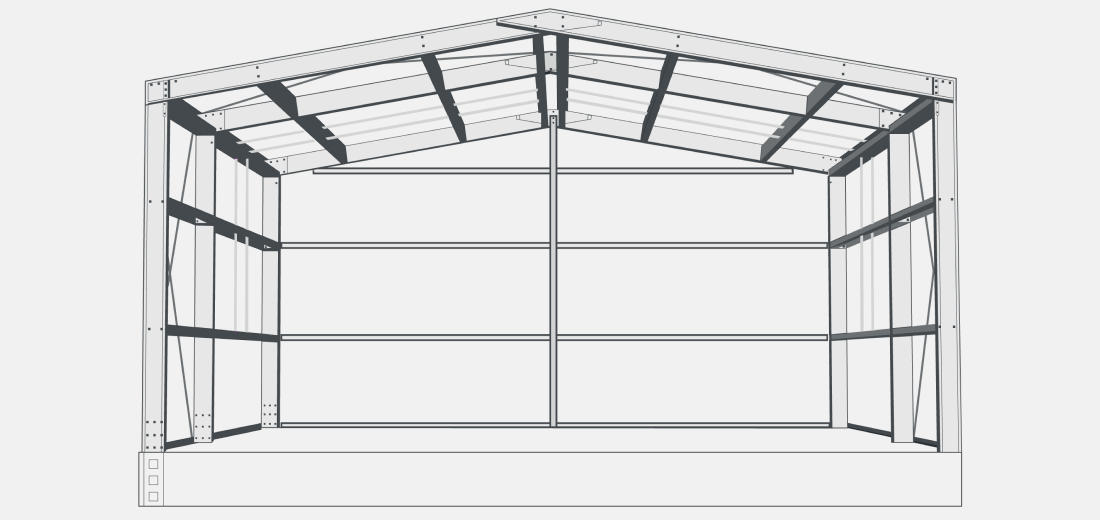

Bracketless Portal System

Maximise your internal space with our Bracketless Portal System.

Created in 2005, our patented efficient and aesthetically unique Bracketless Portal System features cold-formed flat Z450 galvanised coil.

Generally, other cold-rolled structural systems will have a knee or brace strut to support the rafter sections. However, a knee brace limits the usable space in a building, which isn’t ideal for vehicle access or storage space. We understand that internal space is key for any business, and our in-house team of experts developed the Bracketless Portal System with this in mind. This system can help you unlock more internal space and maximise profitability.

Our portal system features nested and directly bolted steel columns and rafters rather than being joined with a bracket. This method allows for a stronger connection between the sections, faster construction times, and reduced labour costs.

Superior Pest Protection.

In addition to more space, this steel portal shed system offers protection against birds and vermin.

The angled shape of our bird-resistant purlins makes it impossible for a bird to perch on, preventing them from roosting in your building.

Instead of using a bottom girt 300mm above the ground, we can incorporate a vermin girt on top of the slab, tying it into the structure. The cladding on the exterior wall will come over the face of the vermin girt. This unique profile prohibits vermin from entering your building, protecting your precious goods and resulting in an easily maintained building that looks great for longer.

The innovative nature of Bracketless Portal Systems means we can create modern designs unique to every project. Over the years, we have produced many steel portal sheds for retail stores, storage facilities, commercial company spaces, and more. Contact Coresteel for more information about how we can create a custom steel portal shed solution for your needs.

Structural Points of Difference

-

Embedded splice plate option

Our strongest and stiffest ground connections. C-Section splice plates are cast into the concrete foundations. The top of the ESP projects sit above the concrete, enabling the portal frame columns to slide over and bolt into position. The alternative to ESPs are Bolted Ground Brackets.

Note: Embedded Splice Plates normally lead to steel weight savings compared to Bolted Ground Brackets. -

Bolted Ground Brackets

Our simplest column connections. They consist of simple angle brackets, which bolt the portal column down to the top of the foundations. The alternative to Bolted Ground Brackets are Embedded Splice Plates (ESPs).

Note: Larger portal frames are normally required when using Bolted Ground Brackets. -

Nested Roof Purlins and Wall Girts

These are nested between the portal frames and bolted into place. They provide a stronger, better-looking building with more usable space between the portal columns. Our competitors typically use purlins and girts screwed to the outside of the portal frame.

-

No Obtrusive Knee Braces or Apex Braces

Unlike our competitors, our Bracketless Portal System doesn’t require obtrusive knee braces or apex braces to support the portal rafter. Other cold-rolled structural systems often use knee braces, which severely limits the amount of usable space within the building. This can cause problems when moving vehicles or providing storage/racking.

-

Bird-Resistant Purlins

Our optional bird-resistant purlins are designed specifically to prevent birds landing or roosting on the purlins.

-

Bracketless Portal System

The Bracketless Portal System offers a more cost-effective option to hot-rolled steel or timber products for nearly every build. Structural sections are prefabricated in a purpose made factory and simply bolted together on site - drastically reducing construction time. The system can be adapted to virtually any size and shape, without compromising the structural integrity of the building. This proven system was designed for simplicity. It looks good as well as making better use of precious raw materials.

-

Fully Bolted (not TEK screwed)

Our structural connections are fully bolted. These make our connections incredibly strong – as well as looking great. Most of our competitors TEK screwed connections, which we avoid.

-

Vermin-Resistant Bottom Girts

Instead of using a c-section as the bottom girt, we can provide proprietary vermin resistant girt. The vermin resistant girt fixes to the slab and acts as the bottom girt as well as replacing the bottom wall flashing.