Ready to start your next project?

Contact us today for a custom design and build, specific to your business requirements.

Like what you see?

Find your nearest franchise and get started on your new steel shed project.

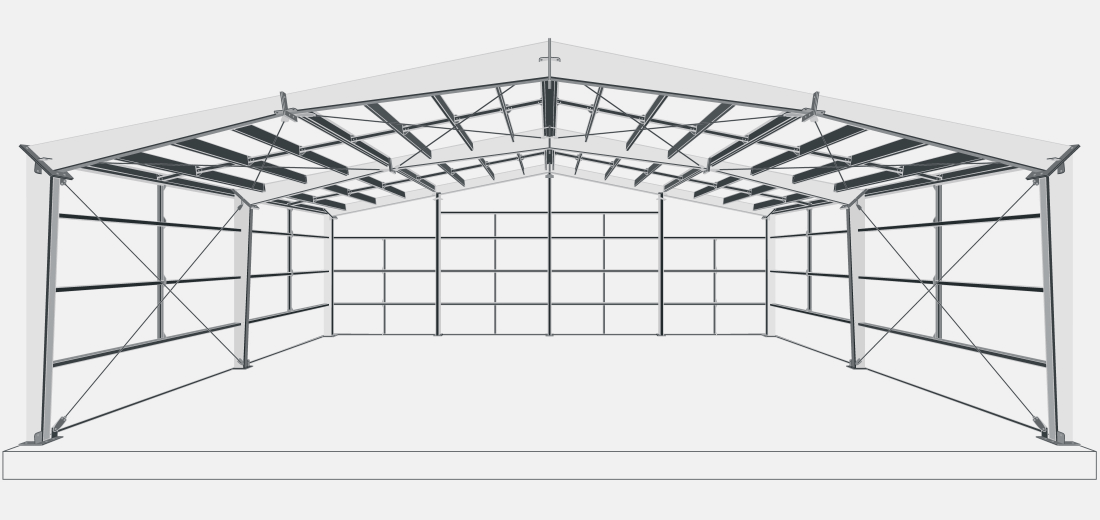

DonoBeam

A tapered box beam manufactured by welding two folded halves of steel plate together to form a box. The innovative DonoBeam design reduces the amount of steel needed, without impacting on structural integrity.

-

DonoBeam's torsional stiffness significantly reduces the need for fly bracing

Traditional I-Beam portal frames tend to buckle rotationally under load and lose their strength. To compensate for this, they require a lot of buckling restraints (fly-bracing) to be installed. DonoBeam is significantly more stiffer rotationally, and can carry high loads with minimal buckling restraint. As a result, DonoBeam buildings also look cleaner and more appealing without the cluttered look of fly-bracing.

-

Reduction in steel weight due to tapering of portal structure

DonoBeam frames are designed to be efficient, providing structural strength where it is required and removing material where it’s not. This reduces the overall weight of the structure and makes better use of Earth’s valuable resources.

-

Fully bolted for easy erection

Our structural connections are fully bolted and structural members appropriately sized for easy handling, transport and erection.

-

Easily partners with DonoBrace® - Donovan Group's tension-only bracing system

DonoBrace is the only steel rod bracing product in Australia and New Zealand which is dynamically tested in a simulated earthquake environment.

-

Bird and vermin-resistant sections

DonoBeam frames are fully sealed box sections making them resistant to birds, vermin, and dust. They can be paired with “bird-proof” purlins to create a complete solution for building owners.

-

Fully-welded tapered section

DonoBeam is manufactured by folding two halves of steel plate and welding them together to form a sealed hollow box section. It is tapered through its length, utilising only the amount of steel required for a given design.

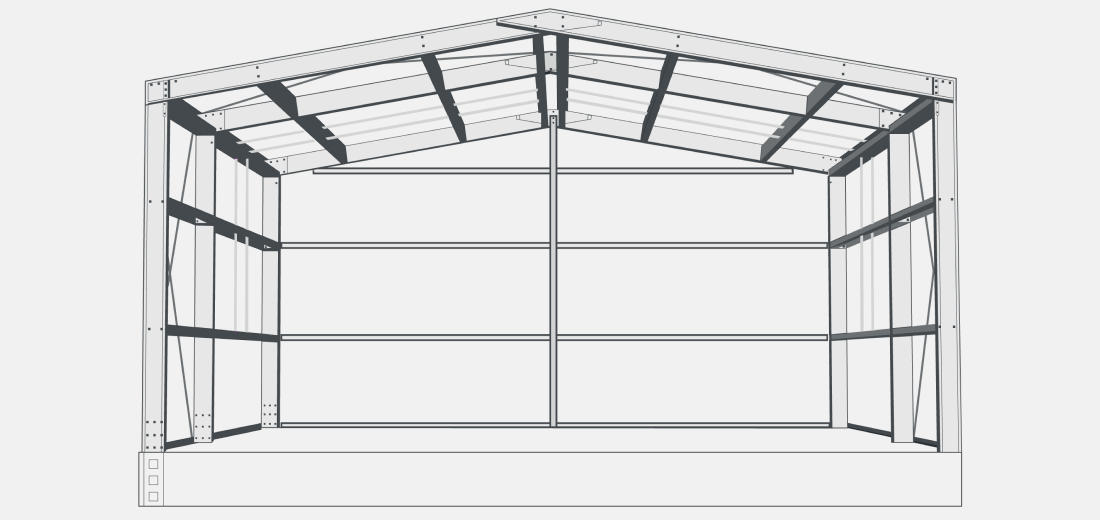

Bracketless Portal System

Created in 2005 constructed using cold-formed flat Z450 galvanised coil, this patented system has been designed for efficiency and appeal.

-

Embedded splice plate option

Our strongest and stiffest ground connections. C-Section splice plates are cast into the concrete foundations. The top of the ESP projects sit above the concrete, enabling the portal frame columns to slide over and bolt into position. The alternative to ESPs are Bolted Ground Brackets.

Note: Embedded Splice Plates normally lead to steel weight savings compared to Bolted Ground Brackets. -

Bolted Ground Brackets

Our simplest column connections. They consist of simple angle brackets, which bolt the portal column down to the top of the foundations. The alternative to Bolted Ground Brackets are Embedded Splice Plates (ESPs).

Note: Larger portal frames are normally required when using Bolted Ground Brackets. -

Nested Roof Purlins and Wall Girts

These are nested between the portal frames and bolted into place. They provide a stronger, better-looking building with more usable space between the portal columns. Our competitors typically use purlins and girts screwed to the outside of the portal frame.

-

No Obtrusive Knee Braces or Apex Braces

Unlike our competitors, our Bracketless Portal System doesn’t require obtrusive knee braces or apex braces to support the portal rafter. Other cold-rolled structural systems often use knee braces, which severely limits the amount of usable space within the building. This can cause problems when moving vehicles or providing storage/racking.

-

Bird-Resistant Purlins

Our optional bird-resistant purlins are designed specifically to prevent birds landing or roosting on the purlins.

-

Bracketless Portal System

The Bracketless Portal System offers a more cost-effective option to hot-rolled steel or timber products for nearly every build. Structural sections are prefabricated in a purpose made factory and simply bolted together on site - drastically reducing construction time. The system can be adapted to virtually any size and shape, without compromising the structural integrity of the building. This proven system was designed for simplicity. It looks good as well as making better use of precious raw materials.

-

Fully Bolted (not TEK screwed)

Our structural connections are fully bolted. These make our connections incredibly strong – as well as looking great. Most of our competitors TEK screwed connections, which we avoid.

-

Vermin-Resistant Bottom Girts

Instead of using a c-section as the bottom girt, we can provide proprietary vermin resistant girt. The vermin resistant girt fixes to the slab and acts as the bottom girt as well as replacing the bottom wall flashing.

Client testimonial

“Working with Logan and Lee from Coresteel has been a godsend. I have found a team that delivers across all aspects of a successful business relationship. Communication, efficiency, cost-effectiveness and quality are all traits that Logan and Lee live by and deliver. ”

Jamie Keehan, Mainfreight, Taupo